From today until Sunday it’s Fashion Revolution Week! We are contributing with our Fashion Revolution blog tour and I am very happy that Lebenskleidung from Berlin makes the start!

I observed the development of Lebenskleidung almost from the very first beginning and have already sewn many garments with fabrics from Lebenskleidung. Just take a look at e.g. the sewing patterns Yogaset Om or the Catrin Shirt.

Certified cotton fabrics as piece goods

Lebenskleidung produces organic cotton fabrics and now also offers a large selection of their great, trendy and at the same time sustainably certified fabrics as piece goods. Not only can you buy the fabrics in retail stores, but you can order them directly online via the Lebensshop webshop.

I asked Benjamin Itter, who founded Lebenskleidung together with Enrico Rima and Christoph Malkowski in 2009, some questions and the interview is so exciting that I do not want to write a long opening credo and start right away.

Interview with Benjamin Itter from Lebenskleidung

Dear Benjamin, you founded “Lebenskleidung” with Enrico Rima and Christoph Malkowski. How did this come about?

Hi Silke, Thank you for your questions. This is a very long story and in fact we are celebrating our 10th anniversary this year. Madness! This story will run a little bit longer and I hope that’s OK.

The very beginning

Everything started with Ayurvedic dyed bedding. In 2006 Enrico and I studied in South Indian Kerala, for one year. This must have been karma, because it was here in India that the idea of “Lebenskleidung” was born. We spent one year as a whole in India, I lived there for another two years, later on. Enrico studied environmental sciences and geography, I myself literature, politics and geography. We were extremely inquisitive and mostly swallowed up the English-language newspapers and travelled a lot. And it was here, for the first time, that we came into contact with all the problems in India, that are, above all, in agriculture: farmers were poisoning themselves in their fields with pesticides and were committing suicide, in masses. Cotton farmers in particular are affected. We wanted to know more, and gradually we became more aware of the interrelationships of the global textile production: the dependencies of commodity prices, the global fluctuations, the huge amounts of cotton that are produced in the southern part of the world, for the rich north. And that was not all. We read about and saw rivers, which were contaminated from the wastewater of the dye factories and also learned of the exploitation of mostly women in the sweatshops. Of course, our time in India was also wonderful and we had a great many positive experiences. But for the first time in our lives we were confronted with poverty and also with the question under which conditions our clothes are actually produced.

Aryurvedic Bedlinen

And somehow we wanted to change something about it at the time, but didn’t really know how to go about it. Our studies abroad came to an end. Enrico was drawn back to Berlin and I stayed in India, where I started a placement company, with a friend. One day, I read an article in the Times of India, about a plant dyeing facility in the jungle of Kerala, which dyes fabrics and clothes according to ancient Ayurvedic principles. This was inconceivably brilliant, because the fabrics even have a healing ability, on contact with skin. I told Enrico and another friend about this and we couldn’t help but think how cool it would be to make bedding from the Ayurvedic dyed fabrics. That was actually the beginning of “Lebenskleidung”, our name derives from the Sanskrit word “Ayurvastra”. “Ayur” means life and “Vastra” clothing. Back in Germany, Christoph who at the time was studying via a night course, at the University of Economics and Law (HWR), joined our company.

Founding of Lebenskleidung

And so in 2008, four guys sitting in an attic apartment in Berlin established the company “Lebenskleidung”. At the beginning we wanted to make Ayurvedic dyed bed linen, famous in Germany. To do this, we had to find the perfect fabric and turn it into bed linen. After a long search we found the “Appachi Cotton Project” in Tamil Nadu. Here, the cotton is grown exactly as we imagined it would be: bio-dynamic, completely without pesticides, in the highest quality and with fixed purchase prices for the farmers. And here, the fabric was also sewn according to fair principles.

At the end of 2008 the first delivery of the Ayurvedic bed linen arrived in Berlin. Unfortunately, it quickly became obvious to us that the world was not waiting for Ayurvedic dyed linen. But there was another interesting finding; people started asking us if they could buy the great fabric of the bedding, separately.

And coincidence, or again karma, now played a big role. A friend gave us a tip of another plant dyeing facility in India. There is a dyeing factory in Gandhi’s homeland of Gujarat, which can not only dye but even print towels and fabrics: “Aura Herbal Wear”. And within a short amount of time and after another visit to India, we had expanded our product portfolio to towels and for the first time, fabrics.

We shared a booth with “Aura” at the 2010 Biofach trade fair, in Nuremberg. And our first big customer was the “Waschbär Umweltversand” and many more interested parties followed, even for the fabrics. In 2011, we were featured on the German Television channel ZDF Neo, where we were able to introduce ourselves on the documentary show “Start Me Up”. And for the first time, textile shops and designers also became aware of the plant-dyed fabrics. But unfortunately, we were soon faced with a bit of a catch.The fabrics were beautiful and 100% certified ecologically, but unfortunately due to the purely vegetable coloring on organic cotton, not really wash and color-genuine and therefore did not meet the high demands of Western European customers. This was a great disappointment, which made it impossible for us to sell plant-dyed materials, because we unfortunately received a lot of complaints.

At the same time, the project “Made in Neukölln” was created in Berlin, at the Rütli School. The school, which was the social focus in Berlin Neukölln, was very much in the spotlight of the media because the unsustainable conditions it was facing. A lot of social projects were being launched there. One of them was “Made in Neukölln” in cooperation with the fashion production agency “Common Works”. The idea of “Made in Neukölln” was simple, to produce and print T-shirts and hoodies, locally in Berlin. To do this, GOTS-certified organic-cotton jersey fabric was needed in black and white. Due to our established network in India, we were able to supply the fabrics, and even had an excess of inventory available.

100% Transperancy

During this time in Berlin, sustainable fashion became rather popular and people started to wonder where their clothes actually came from. Many young local designers showed interest in our first fabric delivery. At that time, we worked out of a small, old apartment in Berlin-Treptow. After many sleepless nights, we set up our first online shop and summarized the material requirements of the design community in our first so-called collective orders. The idea behind this was: “Lebenskleidung” ensured 100% transparency, ensured the traceability of organic cotton, regulated logistics and gave great pleasure to many young designers, as they could finally order certified fabrics, in small order quantities. We combined many individual orders of a fabric and then produced them with our partners.

The challenges grew with the happy customers. Repeat orders followed, but the minimal production quantities for the respective fabrics, could only be achieved with the same omnibus orders. It quickly became apparent that we would have to hold stock for our customers, if we really want to supply fashion labels with cool fabrics and wanted to grow with them. Otherwise, it wouldn’t work. Meanwhile, the fabrics were still being sent to the small apartment, which was bursting out of all its seams and all the fabrics were still being wrapped by hand and shipped from there. A little bit like the story of a garage, only that the garage is filled to the brim with fabric. At that time, we reached our limits. And then we found a partner with GLS Bank, the world’s first bank to finance sustainable companies and projects, who made it possible for our small business, to invest in a proper fabric warehouse. By the end of 2011 things really got exciting. We moved into today’s premises at Leuschnerdamm 13 in Berlin-Kreuzberg. It’s been seven years. Totally crazy how time flies!

Can you tell us about the beginnings? How did you build your network of suppliers and producers? That was certainly pioneering work…?

Oh yes. That was really pioneering work. The textile companies did not take us serious, with our mini-order quantities and often we had to wait in the back of the factory, until a machine was free. Trading in India was not always easy and in addition, we always had to completely finance the fabric for our community. We had to take on the entire risk and if something was wrong with the fabric, we were stuck with it. That was a very big learning curve for all of us.

Pioneering Work from the bottom up

Sourcing of fabrics from India was not really satisfactory in terms of quality control and delivery time. So we had to look for new partners and our perspectives were first directed towards Turkey, where we found a partner, who still works with us today. We travelled a lot, visited cotton fields, embroidery factories, weaving mills, dye factories. Actually, we had to start from the bottom up. Our focus was always on sustainability. And after some disasters, above all: quality, quality, quality. The basis for our partners was first the certification according to the Global Organic Textile Standard (GOTS). But that was never enough for us.

We always wanted to know, who we were working with, who the people were behind the products and whether they were serious about our demands on sustainability and quality or whether they only cared about money. Here we were able to learn a lot in all of these years and there were many ups and downs. This experience is so super valuable, as we have taken out the “sourcing pain” for many companies, today. In Germany we are responsible for the whole process: Delivery times, quality, and certification. There are no trade-offs. Our network has continued to grow and we are now producing many of our fabrics, with family businesses in Portugal. But we also cooperate with partners in Germany, the Czech Republic, France or Belgium. Our assortment is growing steadily and we enjoy finding new fiber mixes and fabrics, we have just added organic cotton from a fair trade project in Uganda. You will find more information regarding that on our blog, shortly.

In our portfolio, which Johanna now plans by herself, we continuously find cool fabrics, every season, in the highest possible certified fabric quality. Personal contact with our producers is the most important thing for us. And in West Germany, we have a strong partner who meticulously checks every delivered meter of fabric, according to international standards, so that only perfect fabrics arrive at the customer, in the highest quality. Finally, all shipments are sent from an external warehouse and samples are sent from Berlin.

The fashion and textile processing industry is still one of the filthiest, with at times precarious working conditions for employees. Despite the consciousness, one has the feeling that the cheap fashion chains are still enjoying great popularity. What are your thoughts, on how one can influence the awareness of young consumers regarding a more sustainable consumption?

I believe that young people in particular have a very strong sense of social injustices and know exactly what is right and wrong. Above all, I always feel that there is a lot of empathy towards the people who are being exploited in the textile industry, once you educate the young people. Nobody wants for other people to suffer, so that something can be produced.

The responsibility must be borne by the companies

The big chains try to keep this, as much as they can, under lock and key and instead prefer to showcase a stylish, fun, individual fashion world. The often insane production conditions are not visible, on the outside. But this is the case with so many things. I don’t think you have to be so strict with young people, either. How are they supposed to make the morally right decisions in a world that is flooded with excitement? We adults should do this. We have to educate our children and show them how it really works. But the responsibility MUST be borne by the companies. It is these companies, whom you have to hold a mirror up to, every day, to remind them of their own Greenwashing lies. If they do not work honestly, we have to rub it under their noses, again and again.

“RankABrand” is a good guide for this. We must not accept that companies exploit people, that there are daily pesticide deaths around the world, that the entire ecosystem is completely destroyed, because we supposedly need cheap t-shirts. There are many alternatives; you can find them in the fair Fashion finder of “getchanged“. And there are so many great examples and so many great labels right next door that do great work. When large fashion chains change, that is even better, but they could do much, much, much more than they currently are.

They have to be responsible with what they do, and can’t just use a random advertising slogans on sustainability, and we can’t just dismiss that. I’ve seen the rivers in India, I know of the situation of the cotton farmers, I am aware of the whole madness of this industry and also of the cynicism of those who make the money in this industry. And that’s mostly the only reason for doing it in the first place, to maximize profit, shareholder value and the usual suspects. Everyone should be able live well from their job and also make profits. However, if they negatively impact both people and the environment, we CANNOT accept that. And at the same time, we need to show great positive examples of how cool, casually fair and properly manufactured clothes can be.

Are you able to see a change of consciousness, with the sale of your fabrics?

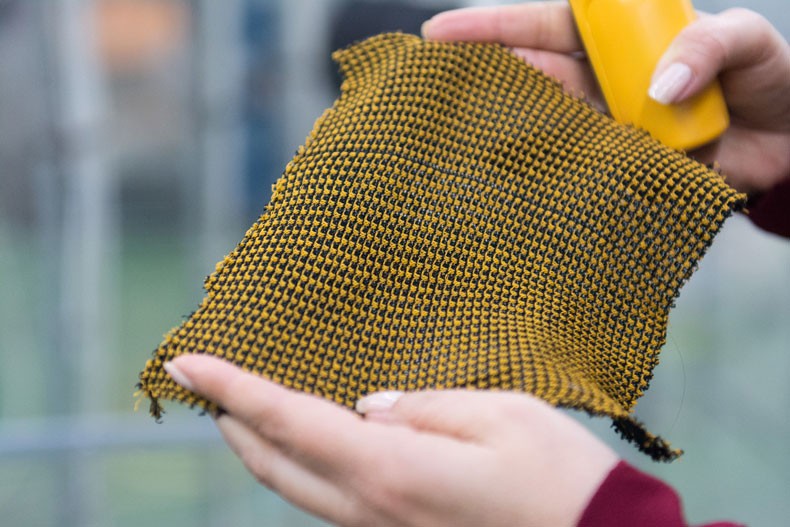

Yes, very clearly. People like to know where their fabrics come from. And when you sew and create you are also a haptical person. If you touch and work with fabric daily, you will also appreciate material that has been produced, properly. And for our brands and labels, which make up the most part of our customers, a very high quality is also extremely important. And that makes a difference, whether I use the best untreated organic cotton, whose yarn has been combed or even compact yarn for whose coloration one uses the best possible techniques such as oxygen bleaching instead of chlorine at the beginning, natural enzymes instead of aggressive plasticizers and much more. Sustainable is only what has quality and is also durable. And so many people just appreciate it and it feels like so many more are, too. That’s great to see.

You also have an online shop for hobby seamstresses and supply the fabric in shops. Do you have the feeling that hobby-sewers in particular are aware of the sustainability of their hobby and subsequently, more and more, are also accessing fair and ecologically clean fabrics?

Yes. Like I said, experiencing, feeling and working with fabric makes you very conscious of what kind of fabric you are dealing with. And it is a great feeling, if your own creation was made with material that is both made fair and ecologically. I find it so incredibly cool when I see the creations that are made using our fabrics, for example, in our Facebook Sewing-Community Group.

The greatest thing about sewing for oneself, is also that individuality is gives us. Even if you sew according to a pattern, you make something for yourself and give each piece its own special touch. And every item that you sew yourself, you no longer have to buy from an anonymous fashion chain. I also find the aesthetic behind it important. Let us reclaim our inner cities, send beauty into the world and put an end to the monotony of clothes out there. Support your local designer. How much nicer would it be if you went to a celebration and each of the guests was really individually dressed? And if it allowed the people who grow the cotton and produce materials, to live a better life?

What do you think are the biggest challenges for your business?

Continuous quality control, and also the logistics.

What would be a fashion revolution for you?

A fashion revolution is already underway. We consumers are asking more and more the right questions and exerting pressure on those who do not work properly and throw too much clothing onto the market, which is often burned or ends up in landfills, even though it was produced under great effort. That’s madness.

A fashion revolution starts with every fashion designer at your house, at your doorstep. If you can know find out how things were produced and which materials were used, that is a fashion revolution. You don’t need cheap advertising slogans, but the people behind the product. We only have one planet and we should all take care of each other.

And here you can quote good old Kant: “Only act in accordance with the maxim through which you can at the same will that it will become a universal law!” or easier: “What you don’t want someone to do to you; you don’t do to anyone else!” If you act like this, it is truly revolutionary, though it is so simple.

Thank you very much, Benjamin, for this great and engaged interview! You put heart and soul into it and I wish you success and a lot of energy to expedite your business and all your great ideas!

Our tipps for you Get Changed & Erlich Textil

GET CHANGED ASSOCIATION FAIR FASHION NETWORK

The Fair Fashion Network is a registered association in Switzerland whose aim is to inform fashion-conscious and critical consumers about the topic of fair fashion and to network interest groups. The basis of the network is the Fair Fashion Finder, which enables consumers to find fair fashion quickly and easily. At the same time, GET CHANGED creates transparency of the social and ecological production conditions of the presented collections. The Fair Fashion Network stands for independence, credibility and transparency and integrates these foundations into entrepreneurial action. Since October 2014, www.getchanged.net is managed by the Fair Fashion Network association.

***

lingerie & basics, which just feel better – and this in all respects. With this in mind, Sarah and Benjamin began working on a label for lingerie in 2015. In weeks of material science, color patterns, button engravings, sample amounts, washing and rehearsing, the first collection of sustainably produced underwear for men and women was created.

Erlich Textil lingerie is unpretentiously timelessly designed and thought out detailing lingerie products with a restrained design and natural sex appeal. They are timeless by their very high quality and design and do not follow short-term fashion trends.

***

Thomas won the Floor Shirt von Kuyichi Pure Goods. Congratulations!